The LUMiReader X-Ray is the first dispersion analyser designed for one purpose only: to study dispersability, stability, separation, and consolidation phenomena for completely transparent to completely opaque emulsions, suspension, sludges, slurries, foams and powders in real-time. For the first time ever, illuminate your sample instantaneously from top to bottom. Solve your most challenging dispersion problems with complete insight. Go places light cannot.

Our patented solution combines X-ray vision with the proven STEP-Technology®, permitting highest spatial resolution, short sampling intervals and powerful detection technique. The LUMiReader X-Ray employs monochrome and parallel X-rays with the help of a special crystal.

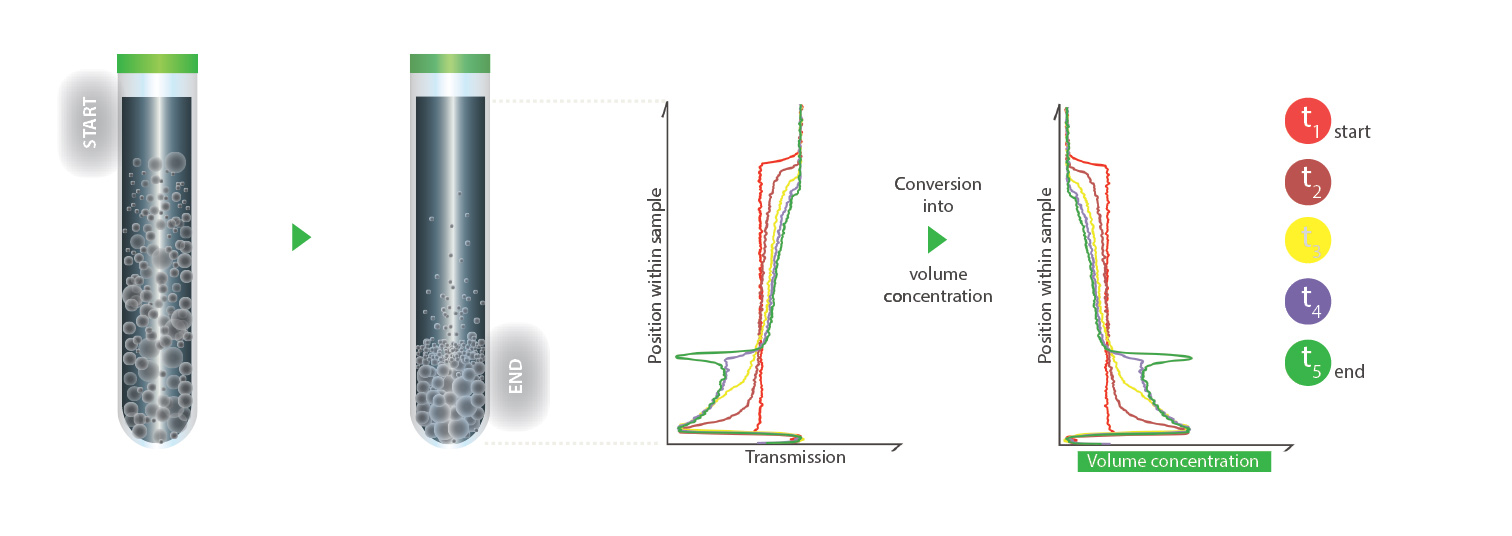

More than 1,600 detectors record the transmitted beam, giving an unprecedented resolution over the entire sample cell of 20 mm height. Kinetics of instantaneous recorded transmission profiles across your whole sample are converted into stability and separation rates. Particle concentration, sediment packing density and X-ray attenuation can also be calculated based on the extinction profiles.

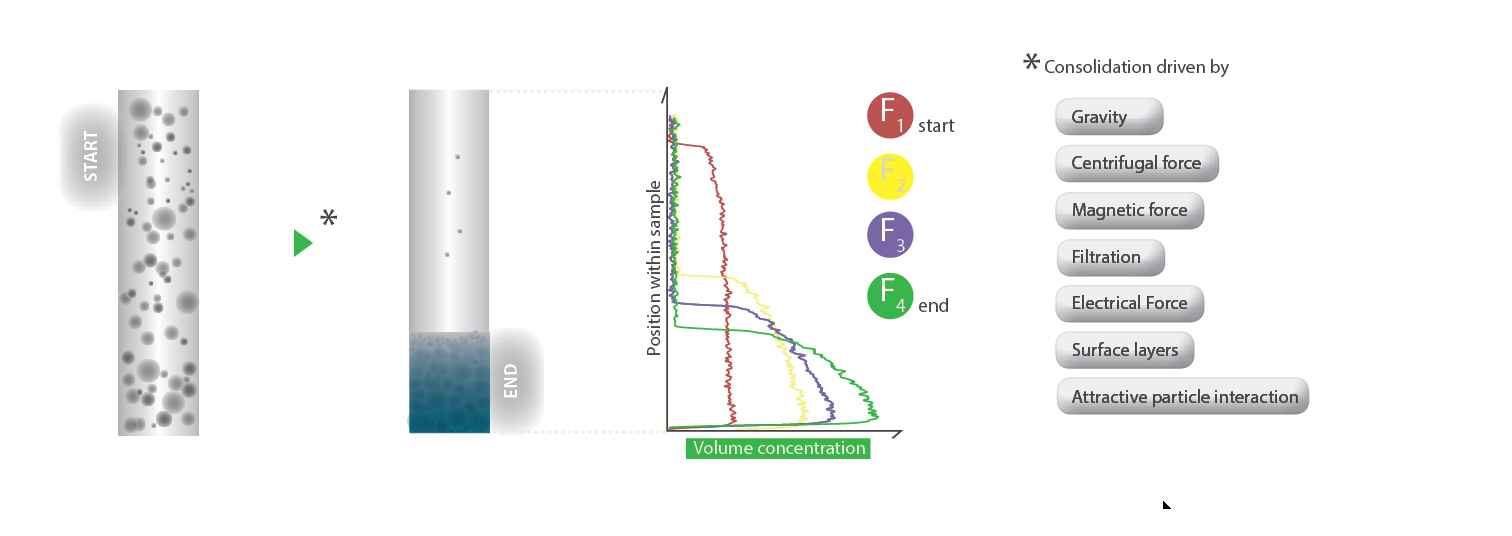

The obtained Space- and Time-resolved Extinction Profiles allow you to measure and understand particle stability, phase separation, and sediment consolidation in systems that where up to now, unknown frontiers of science and technology.

You now can optimize your formulation, measure its stability, and perform accurate shelf life tests, regardless of the shape or concentration of your dispersed particles and droplets. In-situ, real-time, non-invasive and non-destructive.

Typical applications are ceramics, cosmetics, pharmaceutics, paint & pigments, construction materials and fillers, as well as mining and petrol industry dealing with complex emulsions, slurries and sludges.

No more dilutions, no more guess work, no more unexpected surprises. Analyse and understand your sample as is, no matter how opaque or concentrated your formulation is.

For all those instances where you need to understand opaque dispersions, foams, emulsions, or clear microemulsions where dilution is impossible or has unknown side-effects and consequences there is a solution now, and you are looking right at it.

There are many claims out there about the ability to analyze concentrated systems. When pressed however, it turns out that what is concentrated to one person is dilute to another. With that in mind, and wanting to avoid any confusion, all we can state unequivocally is that the LUMiReader X-Ray was designed with one goal in mind: to allow you to analyze and understand concentrated and totally opaque emulsions and suspensions.

How concentrated? As high as you want to go. As opaque as you want it to be. Top to bottom, instantaneously. Yes. Really. No other technology can do this. It is not even close.

The LUMiReader X-Ray is simple to operate. It comes certified, factory pre-calibrated and is ready-to-go.

Comes with state-of-the-art software SEPView (Click icon to find out more). ![]()

The LUMiReader X-Ray comes certified, factory pre-calibrated and is ready-to-go.

A full protection security circle certified by PTB – the national metrology institute providing scientific and technical services and BfS - Federal Office for Radiation Protection guards the user so anyone can employ the instrument free of risk and without worries about the X-ray radiation. No specific training course about x-ray instrumentation, nor any special operation licenses are required by the user.

A thick lead layer shields the environment from the X-ray exposure inside the apparatus. Because of this and various other safety designs, there is no detectable energy dose outside the instrument. State of the art interlocks sentinelling the sample lid position and the X-ray tube shutter action. Opening the lid during a measurement causes an immediate shut down of the shutter and the X-ray source, triggered by the sentinel circuit independet from software and user.

Here you find different examples of X-ray measurements single and combined with centrifugal consolidation

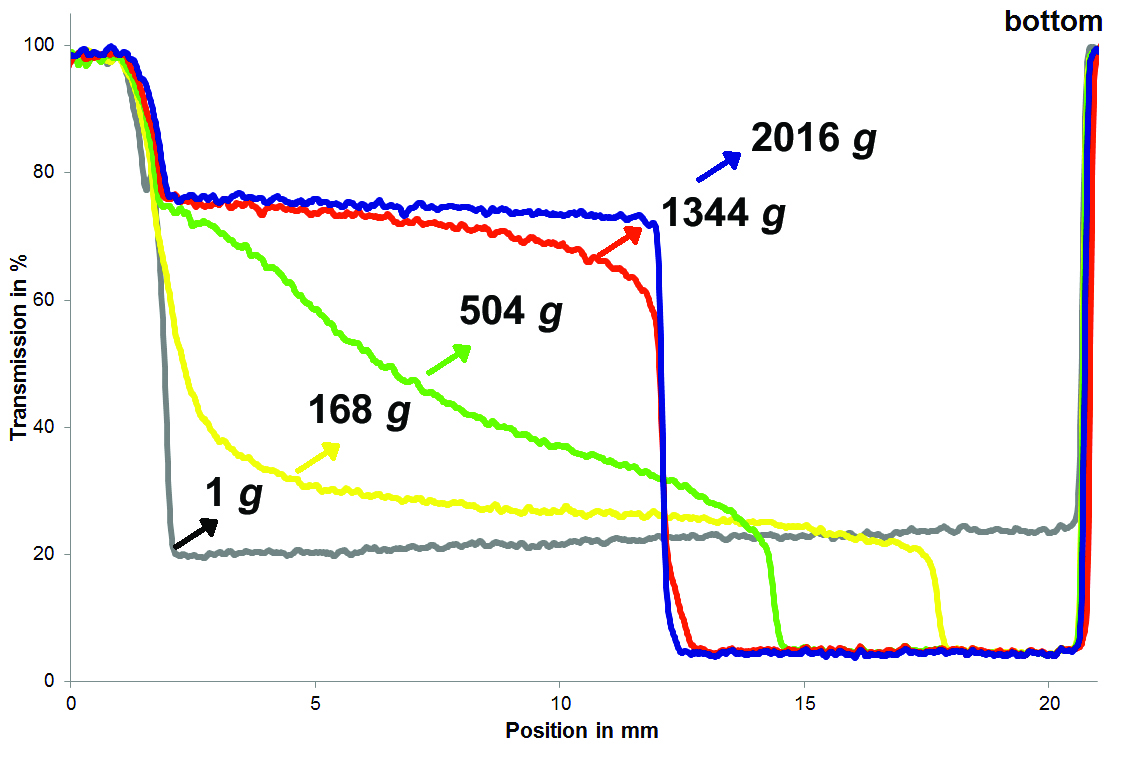

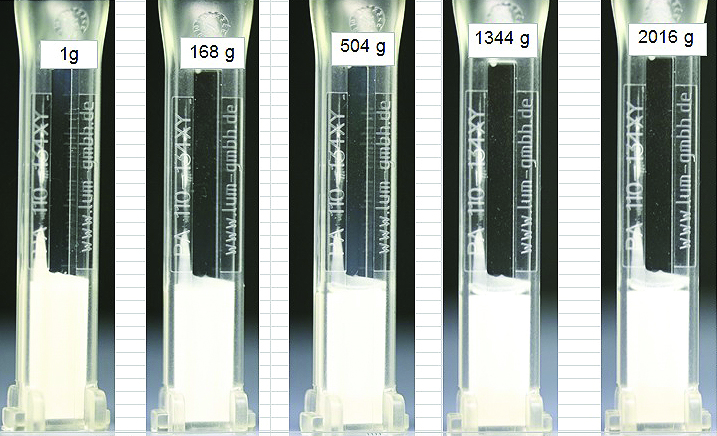

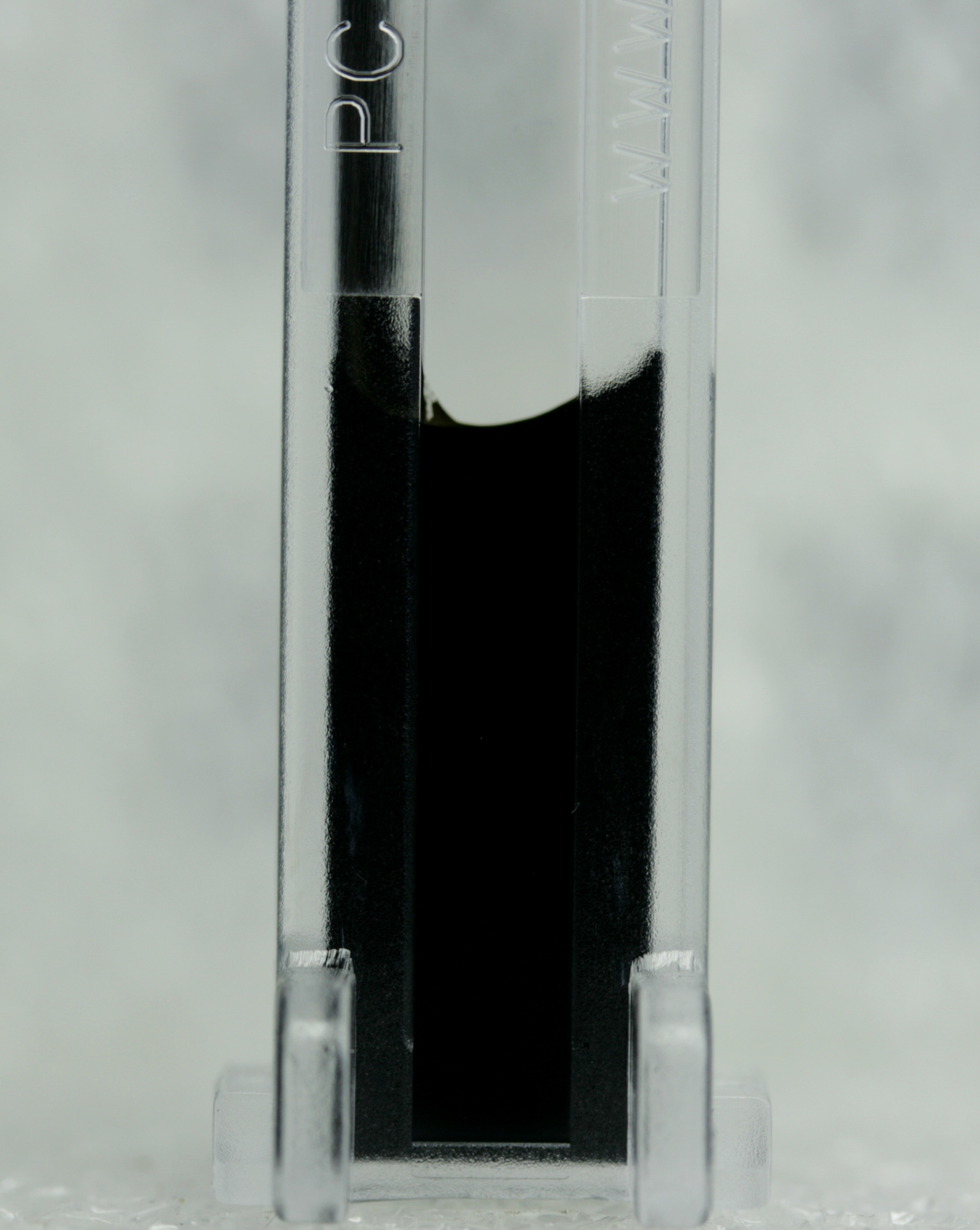

X-ray phase detection of ongoing clarification and sediment growth (left) within even opaque systems (right)

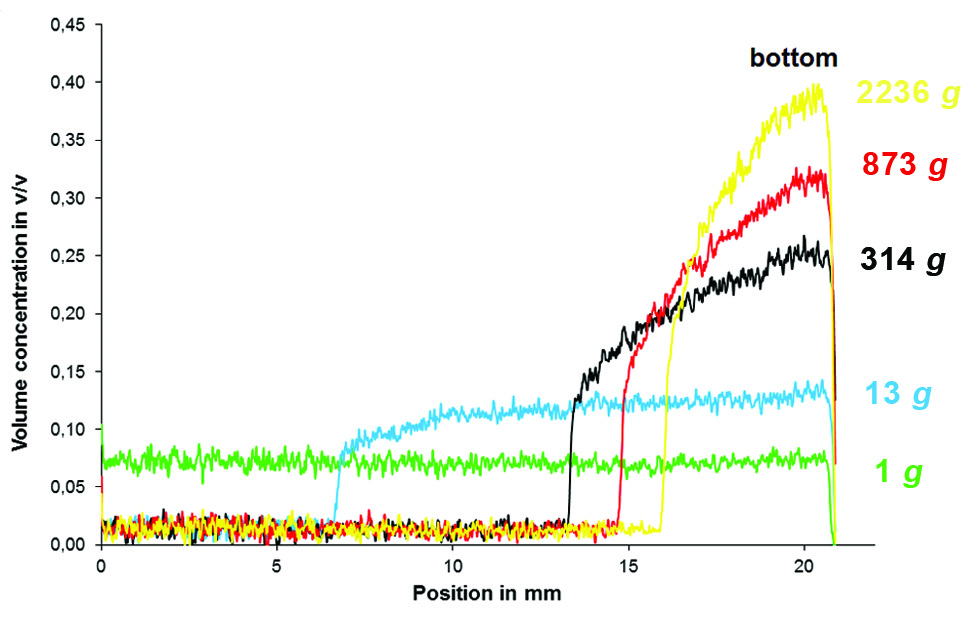

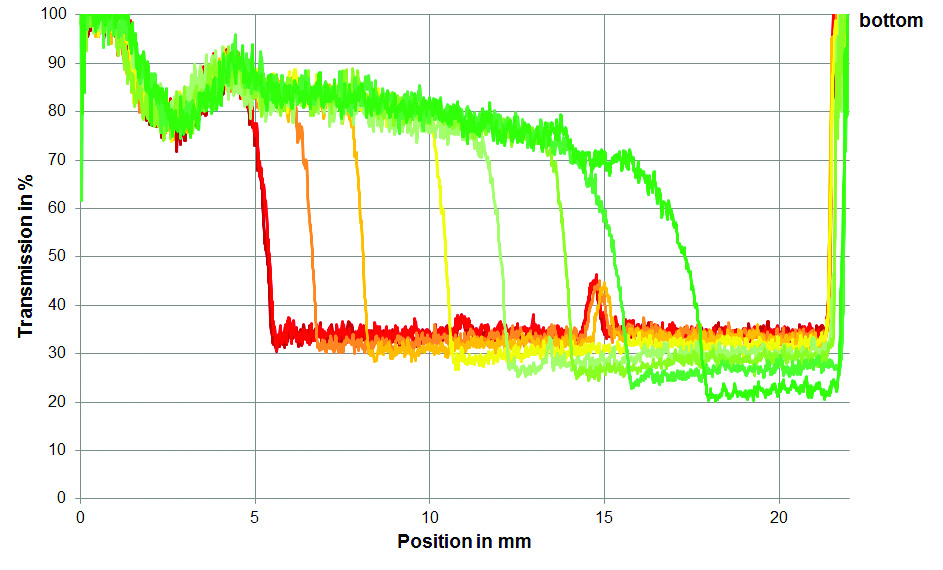

Packing density gradients of lime after centrifugal consolidation

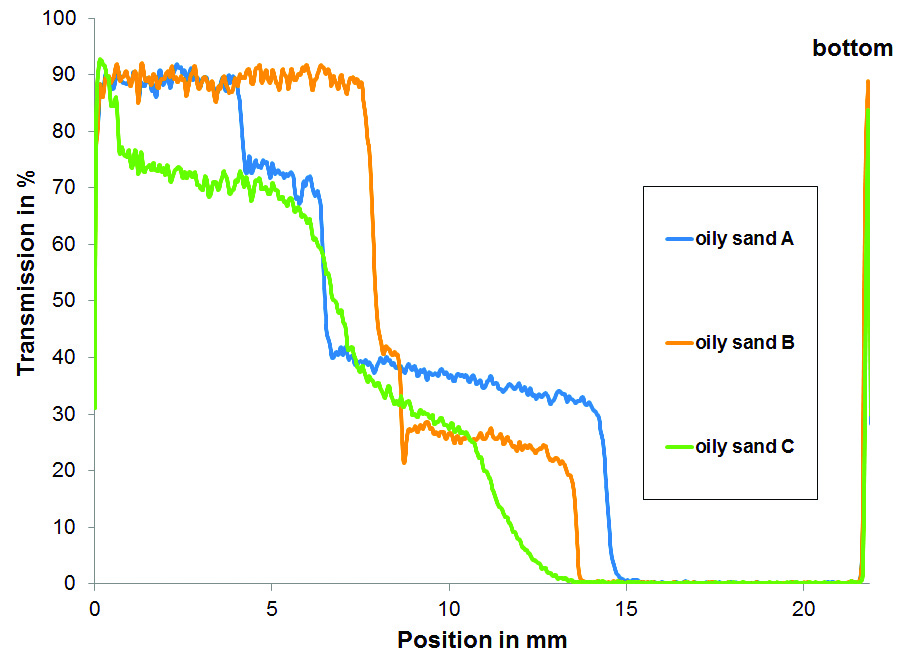

Visual appearance and x-ray intensity profiles of oil sands after separation

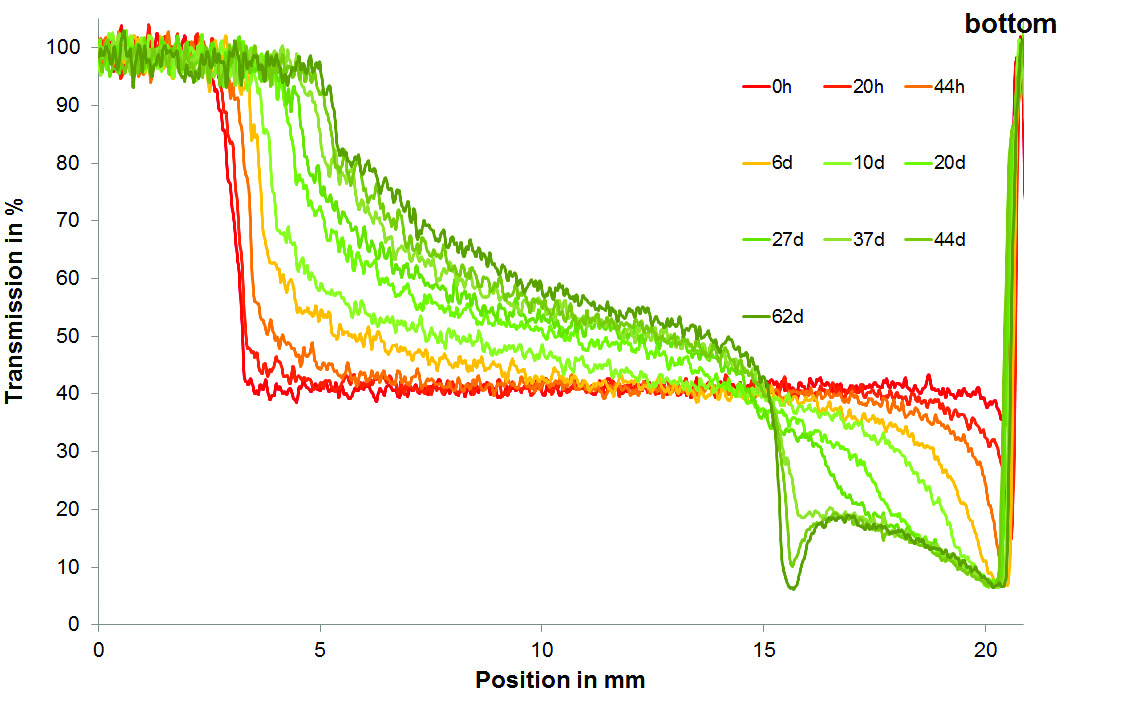

Phase and sediment formation of polymer dispersion

Phase separation of MoS2-Graphit suspension

- Abrasives

- Batteries

- Carbon black

- Catalysts

- Coated particles

- Cosmetics

- Ceramics

- Construction materials

- Lubricants

- Magnetic particles

- Microemulsions

- Metals

- Mineral powders

- Nanosuspensions

- Oil sands

- Paints

- Pigments

- Rigid foams

- Silicone emulsions

- Solid electrolytes

- In-situ analysis of transparent as well as opaque particulate systems

- No dilution of emulsions or suspensions

- Signal does not depend on particle shape

- See/understand complex dispersion behaviour

- Study the various instability mechanisms

- High resolution of phase separation of multicomponent systems

- Detect concentration gradients within phases and sediment

- Determine mean and space resolved packing sediment densities

- Endless monitoring of sample behaviour for long-time storage information

- Use any continuous phase of dispersing agent

- Real time, non-invasive and non destructive

- High-end analyser for QC, process monitoring and R & D